The ultrasonic straight screen is based on a straight screen as the main machine, and an ultrasonic generator is installed. The transducer of the machine is an upper type, and the material under the screen can be quickly and directly discharged, which can greatly improve the screening efficiency. After the ultrasonic generator is installed, it can also effectively solve the screening problems such as strong adsorption, easy agglomeration, high static electricity, high precision, high density and light specific gravity. 2-10 times higher. Dry powder particle size can be classified to 25μm (600 mesh).

The ultrasonic straight screen is based on a straight screen as the main machine, and an ultrasonic generator is installed. The transducer of the machine is an upper type, and the material under the screen can be quickly and directly discharged, which can greatly improve the screening efficiency. After the ultrasonic generator is installed, it can also effectively solve the screening problems such as strong adsorption, easy agglomeration, high static electricity, high precision, high density and light specific gravity. 2-10 times higher. Dry powder particle size can be classified to 25μm (600 mesh).

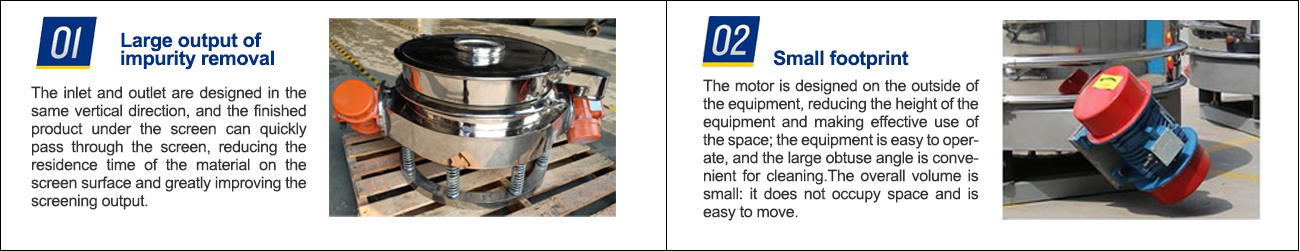

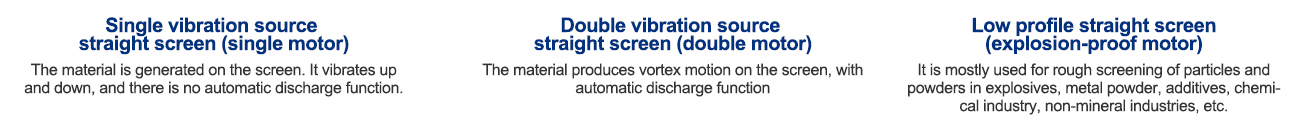

● The optimized dual-motor balance structure is adopted, and the running track of the material has various adjustment forms;

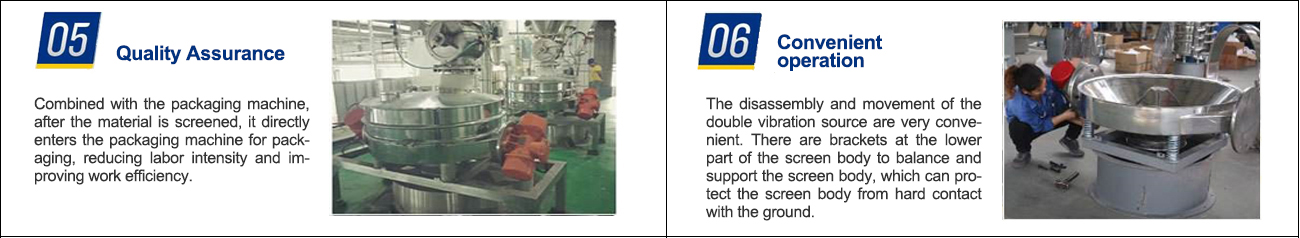

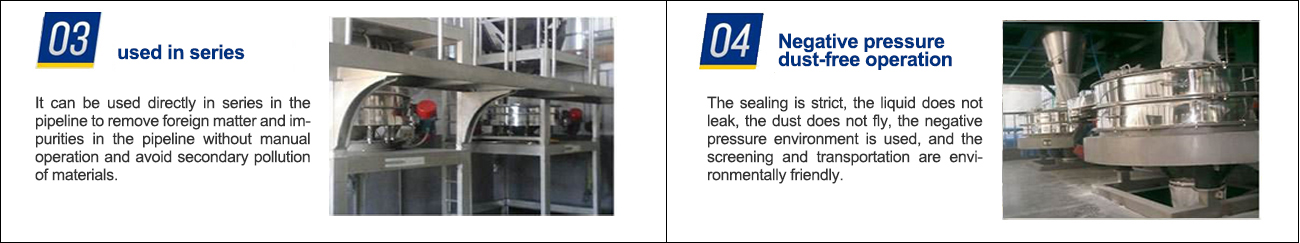

● The material is discharged directly downward without resistance in the central part of the sieve machine, which is convenient for unloading and easy to combine with the production line;

● Compared with other screening equipment, the screening phase ratio of materials with less material content on the Internet has obvious advantages in production capacity;

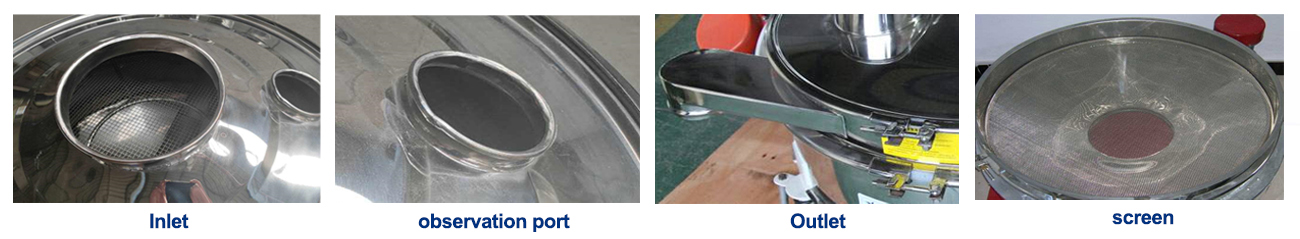

●The whole machine has a fully enclosed structure, which can be continuously fed into production, with low noise and low energy consumption during work;

● It is suitable for vertical discharging, buffering, separating large particles, uniform feeding, mixing, etc. in industrial production.

| Model | Effective screen diameter(mm) | layer | Motor Power (KW) | Dimensions (Lmm*Wmm*Hmm) |

| CF-CZPS-106 | 560 | 1 | 0.15kw*2 | 740*600*560 |

| CF-CZPS-108 | 760 | 1 | 0.37kw*2 | 1010*800*600 |

| CF-CZPS-110 | 930 | 1 | 0.40kw*2 | 1200*970*640 |

| CF-CZPS-120 | 1130 | 1 | 0.40kw*2 | 1430*1170*700 |

| CF-CZPS-115 | 1430 | 1 | 0.55kw*2 | 1780*1470*760 |

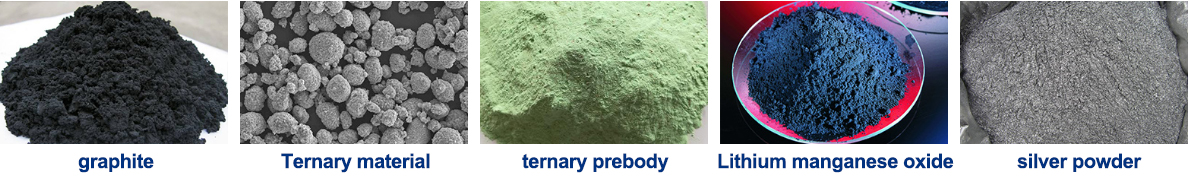

Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, non-metal industry, other industries, etc. Application materials: Alloy powder, starch, flour, molybdenum powder, metal powder, additives, stainless steel powder, tungsten powder, nickel powder, cobalt powder, powder coating, quartz powder, butyl ketone powder, malt powder, coffee powder, electromagnetic powder, negative electrode material, 200 - 600 mesh ultrafine powder such as laser powder is screened, precision screening, large processing capacity, easy to combine with the production line etc.

Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, non-metal industry, other industries, etc. Application materials: Alloy powder, starch, flour, molybdenum powder, metal powder, additives, stainless steel powder, tungsten powder, nickel powder, cobalt powder, powder coating, quartz powder, butyl ketone powder, malt powder, coffee powder, electromagnetic powder, negative electrode material, 200 - 600 mesh ultrafine powder such as laser powder is screened, precision screening, large processing capacity, easy to combine with the production line etc.